R&D Center

A competent product design represents excellent performance and practicality, thus empowering a product’s robustness. Vasworld puts our focus on core technology for production design, manufacturing, and quality control management, endeavoring to foster every successful and influential brand.

- Home

- R&D

Battery R&D Insitute of Vasworld Power

Consisting of four centers, an R&D center, a testing center, an industrial design center and technology center, and one technology department, Vasworld Power Institute was formally established in 2020.

For now, Vasworld has been powered by more than 100 technical workers, and 50 mid-level and senior engineers, with an average working experience of 15 years.

To support the in-depth perfection of our battery products, Vasworld has imported cutting-edge machines, vigorously promoting our battery products. And this makes Vasworld a reliable battery solution provider for your projects.

Internal Structure Design

Perfected Positive Plate

You expect full power every time. Vasworld provides the energy you need.

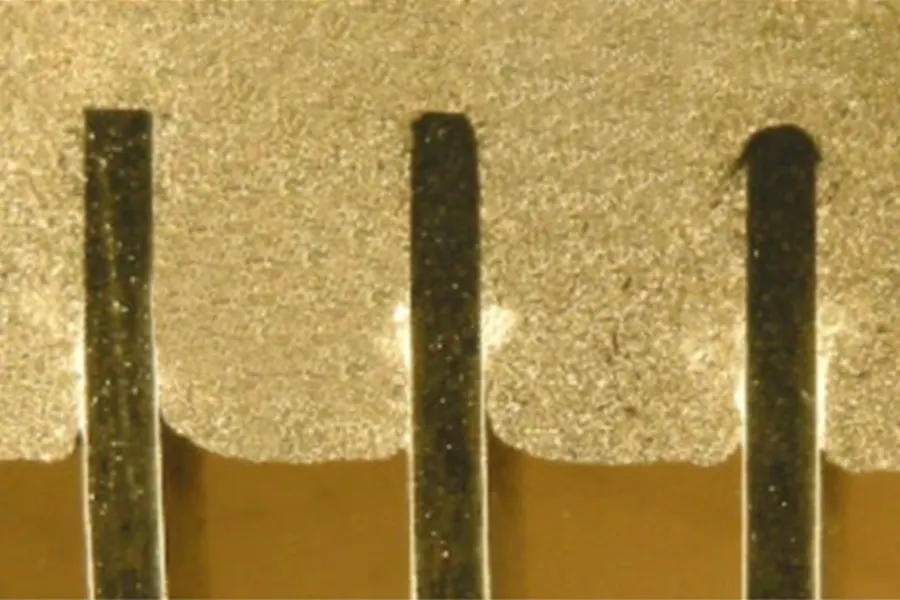

Stamped grid technology is an essential process during battery plate manufacturing. By perfecting the stress point for the positive grid, our grid is proven to be more corrosion-resistant and resilient, delivering more cranking power.

Specific Steam Tech for Positive Plates

Every battery is designed for better durability and a longer lifespan, and that’s what every user is also hoping for. Steaming tech in manufacturing positive plates promotes the stickiness of gel lead, which exhibits high resistance to disturbance and vibration.

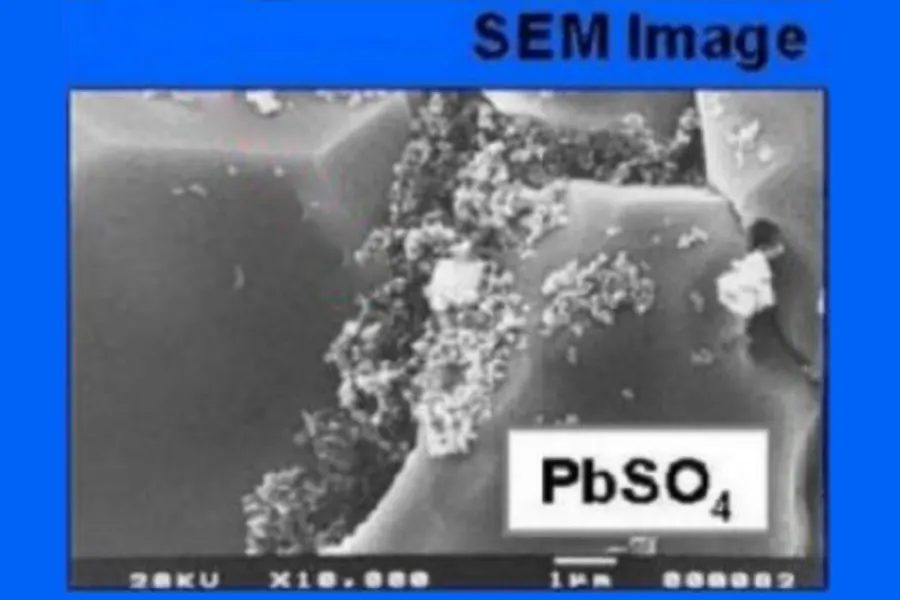

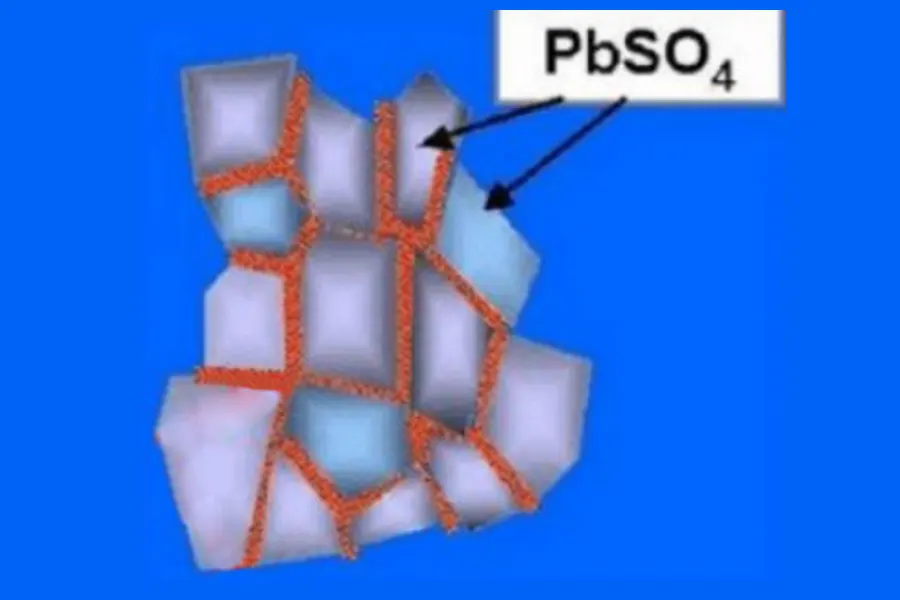

Refined Positive Plate

Refined positive plate with coarser lead sulfate, less coverage surface, more resilient and longer lifespan.

Rugular Positive Plate

Regular positive plate with small grain, larger surface and shorter life.

Improved Negative Plate

A positive plate dose does not work alone. A negative plate is added with specific Carbon to extend its coverage to activate and speed up the electrochemical process and produce electricity, allowing free and steady electrolyte flow while charging.

Enhanced Plate Lugs

By employing and plating anti-corrosion alloy, the batteries made are proven to have a longer lifespan, and they’re also safer for end users.

Previous Design

Optimized Design

Quality Control

Lead Alloy Strips Storage

It’s not demanding when it comes to storing lead alloys, but sometimes it can be neglected.

To produce strong and resilient grids, our engineers take care of this very simple step which is storing lead alloy strips at an optimal low temperature. And it’s this simple step that enables us to make every robust battery.

Storing Lead Alloy Strips At Low Temperature

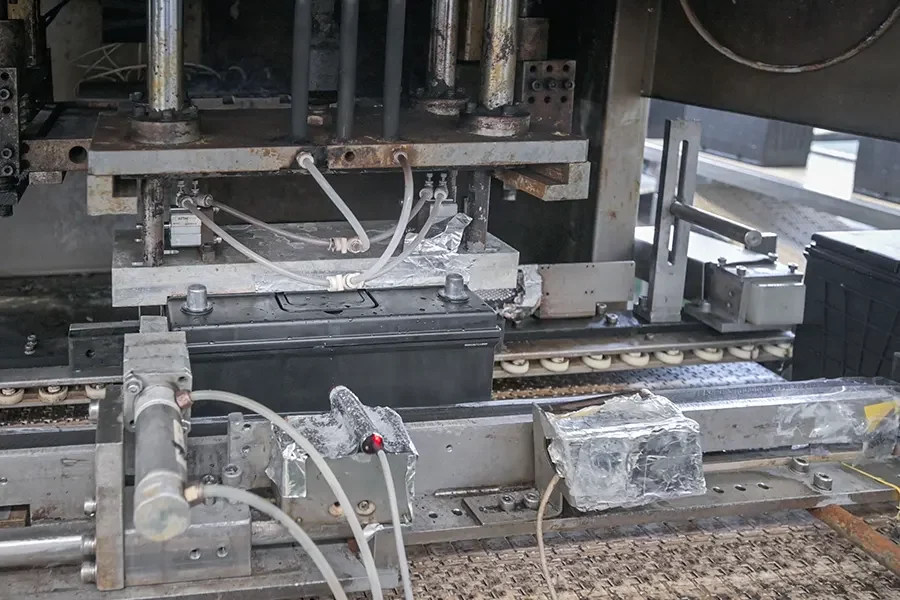

Firmly Sealed Lid & Pressure Test

Each of our batteries is double sealed so that the electrolyte in the cell doesn’t leak and keeps the battery safe and durable. After the double lid is applied, the battery is pressure tested to confirm it has been sealed correctly.

Battery Load Testing

After cleaning, and before the label is applied, the battery needs to undergo load testing to ensure it has the proper CCA.

Staff Training

Every staff in Vasworld Power is responsible for both our and our clients’ prosperity, and that’s why regular training is needed.

Holding regular meetings at least three times a month, Vasworld Power aims to assist every staff, not only engineers, to keep track of contemporary job-relevant skills. For example, computer science, project management, innovation, software engineering, data science & analysis, and so on.